This page is not compatible with Internet Explorer.

For security reasons, we recommend that you use an up-to-date browser, such as Microsoft Edge, Google Chrome, Safari, or Mozilla Firefox.

Analyzing, Testing, Measuring

with Volume Graphics Software for Industrial CT

Why CT?

The Most Advanced Technology for 3D Inspection

Whatever it is you’re making, industrial computed tomography (CT) scanning— when combined with data analysis and visualization capabilities of Volume Graphics software—provides the final word on quality assurance and the supply of competitive products to your customers. By accurately representing both outer surfaces and inner structures, CT offers the unique possibility of getting a full understanding of your product's quality, whether it's an engine block or solder joints on printed circuit boards.

Because CT reconstruction produces a complete representation of a component in 3D based on a large number of 2D X-ray images, CT allows you to answer even the most complex questions about the external and internal structures of a component and its material properties. The process of CT scanning is fast, sensitive, reliable, non-contact, and non-destructive. You can apply it at any stage of production, from prototyping to testing inline on the shop floor. The variety of potential applications for industrial CT data analysis is broad and continually expanding.

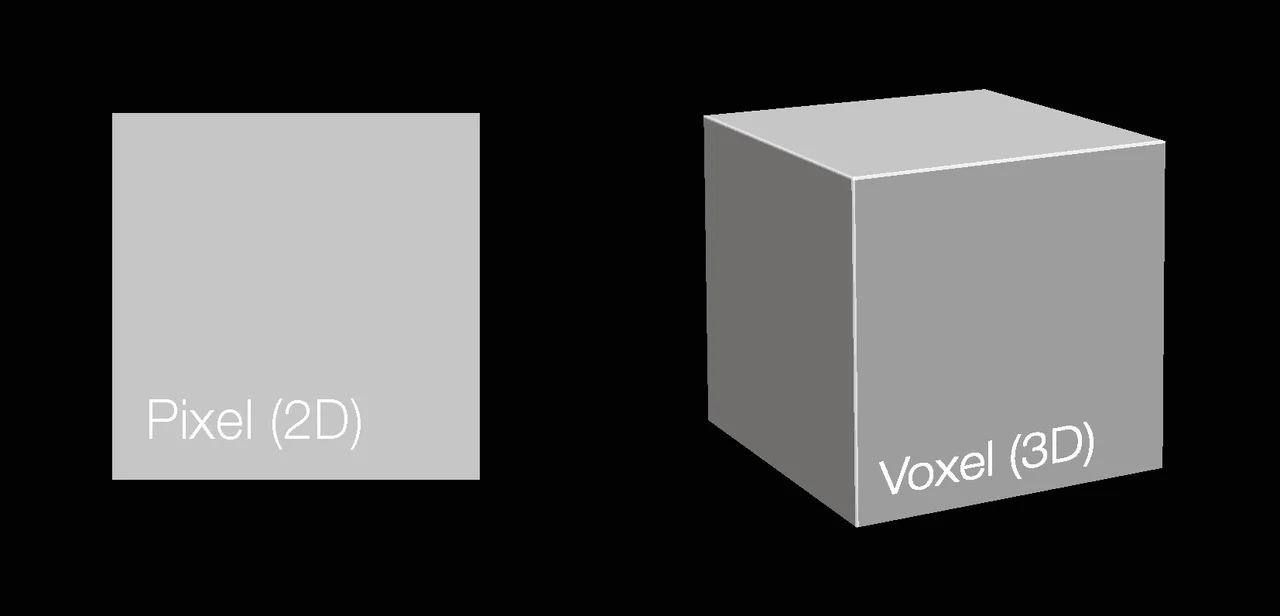

The voxel is key to the CT scan. When an X-ray beam’s high-energy photons pass through their target, some are absorbed while others scatter, but the remaining photons strike the detector screen opposite the X-ray source. They then energize the (two-dimensional) pixels there in proportion to the density of the material being scanned as well as its thickness and attenuation values, generating a series of grayscale images. Software then reconstructs those millions of pixels into three-dimensional voxels, which make up a comprehensive, three-dimensional visualization of the scanned object. Yet to get measurements, find defects, create meshes, or perform simulations, you need the advanced analysis and visualization software provided by Volume Graphics.

With its fully integrated CT reconstruction function, Volume Graphics offers a seamless connection from the CT scanner to the comprehensive analysis and measurement functions of its software. Moreover, the software works with different CT systems from various manufacturers. Most major CT system providers sell Volume Graphics software together with their hardware. In addition, we rely on a worldwide network of distributors to serve our customers around the globe.

CT at All Stages of a Product Life Cycle

For Comprehensive Insights at Every Stage

A More Efficient Look Inside

Analyze Faster and Cost-Effectively with Volume Graphics Software

Like many of our customers, you too can save time and money by using industrial CT. This highly precise, non-destructive technology looks inside your products and finds defects that would otherwise remain hidden when using other inspection methods. However, industrial CT can only reveal its full potential when combined with the right software. Volume Graphics software is your key to unlocking this potential. Customers use our software on objects small and large, simple and complex. It works on parts made of metal, plastic, and composite materials—or all of them together.

Performing analysis tasks directly on voxel data not only opens up possibilities that go way beyond conventional destructive or other non-destructive methods—it also comes with notable efficiency benefits.*

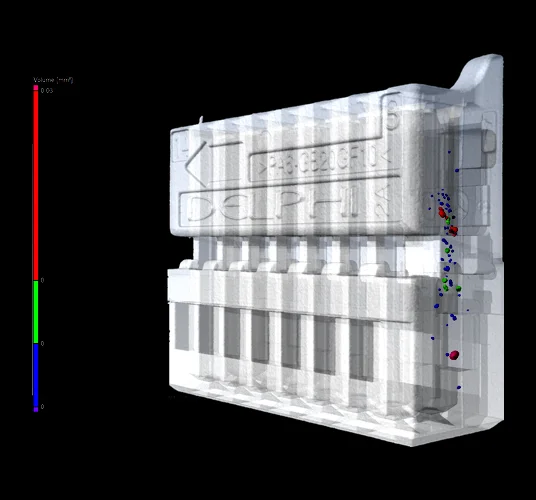

An automotive supplier uses industrial CT in combination with VGSTUDIO MAX to measure its connectors and their 1,200 measurement features.

Inspection Costs Reduced by 50%

An Austrian automotive supplier reduced costs by around 50% after introducing industrial computed tomography (CT) as a measurement tool. Measurements using conventional optical and tactile inspection methods took 450 man-hours for the initial acceptance alone and destroyed the part in the process. Industrial CT provides insight into virtually all features of the part without destroying it—and at lower costs. With the help of CT data and the macro and batch functionality of VGSTUDIO MAX, the same process only took 100 man-hours with only 80 more man-hours needed for final acceptance.

An automotive supplier uses industrial CT and Volume Graphics software to inspect several hundred individual features on the connector .

Inspection Time Decreased by 84%

This automotive supplier went from slice sectioning to using industrial CT-based metrology to inspect its plastic connectors—and thereby reduced the time needed for first article inspection from 75 to 12 man-hours while simultaneously improving measuring accuracy. This increase in speed was achieved in part by using the highly efficient measuring template functions of Volume Graphics software to inspect several hundred individual features of each connector.

*The examples are not meant to be representative. Actual efficiency gains are highly individual and vary from case to case.

Volume Graphics Software for Industrial CT

From design to serial production, Volume Graphics software enables you to keep the quality high by gaining full insight into your products at every step of the production process—all over the world.

With the Volume Graphics product family, composed of VGSTUDIO MAX, VGSTUDIO, VGMETROLOGY, VGinLINE, and myVGL, you can perform all kinds of analyses and visualizations directly on industrial CT data.

Volume Graphics customers in both industry and science know that Volume Graphics software gives them a decisive advantage: the ability to gain reliable insights and make better products. It’s time you join them.

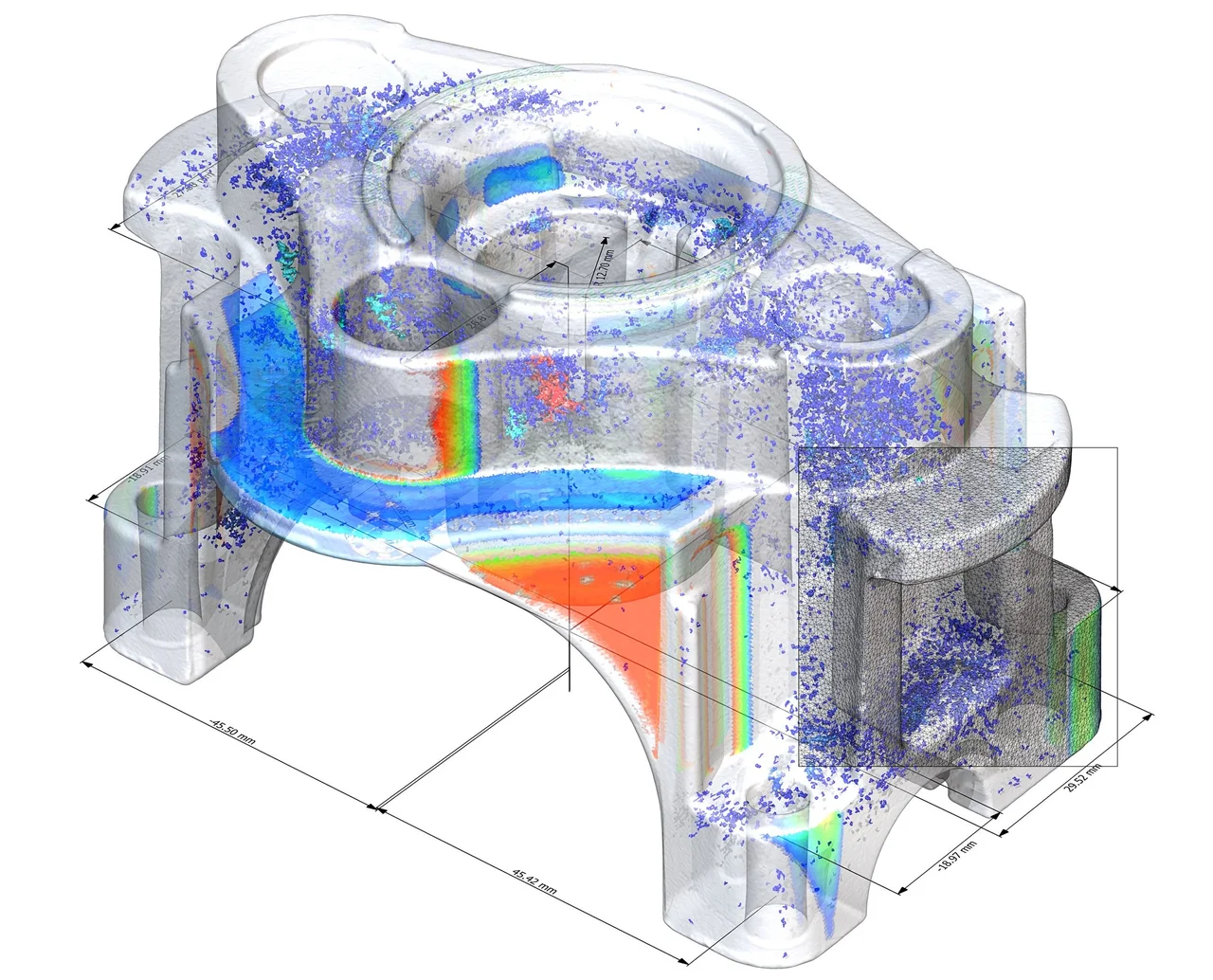

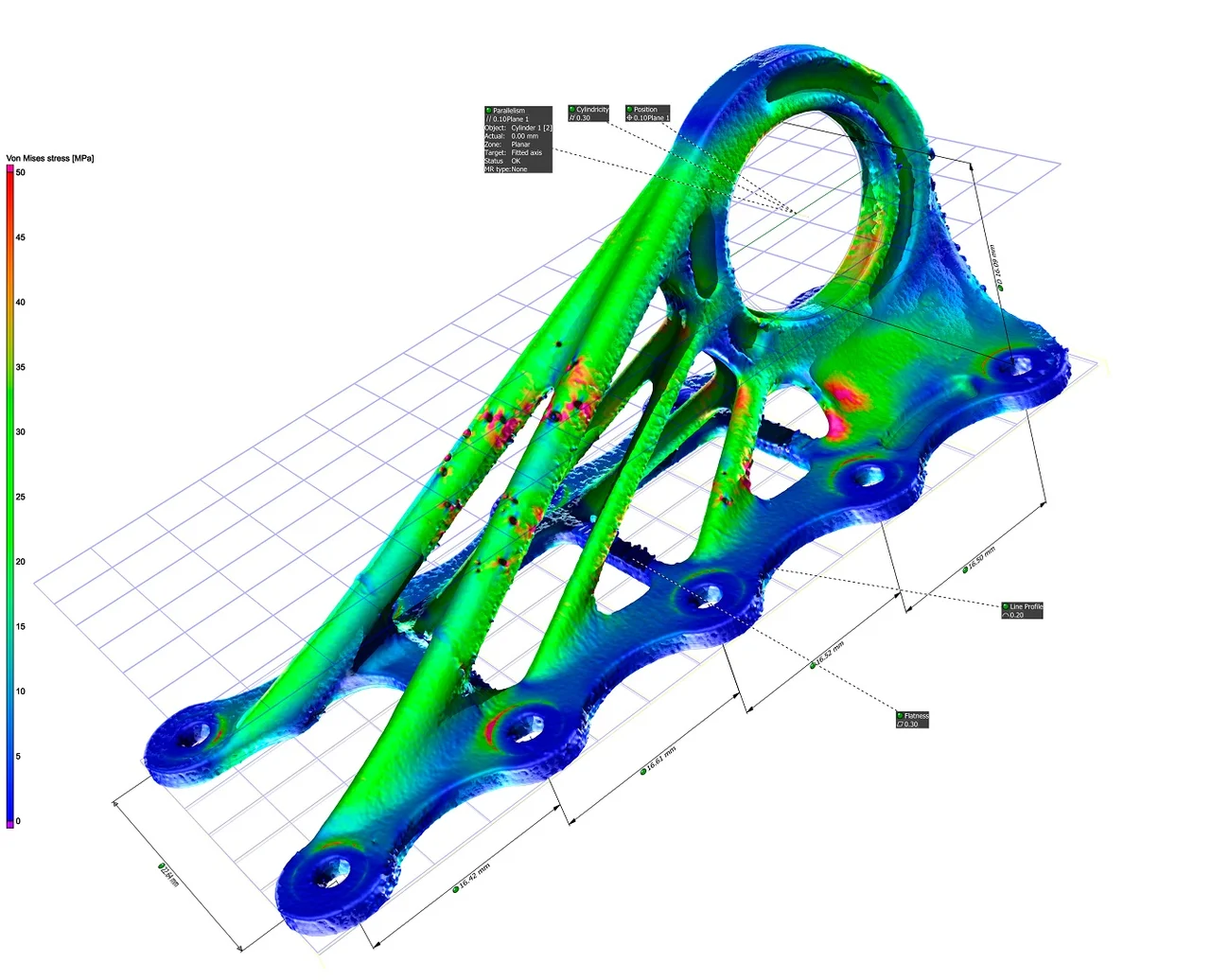

Cast parts with color-coded results for dimensional measurements, wall thickness analysis, 3D porosity inspection, and effect of defect simulation

Benefits of Volume Graphics Software

Color-coded display of the locations of the weak points directly on the scan of an additively manufactured cabin bracket

Your products’ quality faces numerous and challenging demands. Volume Graphics software provides you with the reliable results you need to make the right decisions to meet those demands. Whether you are using the all-encompassing technology of CT or other 3D data formats such as point cloud, mesh, and CAD, Volume Graphics software covers all your requirements related to metrology, defect detection and assessment, material properties, and simulations in a single software. All of its analysis, simulation, and visualization tools fit perfectly into your digital workflow.

A Future-Proof Investment That Provides Efficient Workflows to Tackle Your Challenges

Future-Proof

- Leading developer of CT analysis and visualization software

- Comprehensive scope of functionalities for all current and future tasks of CT data analysis

- Stepwise functional extensions based on a modular product concept

- CT hardware-independent, compatible with different CT systems from various manufacturers

- Strong hardware partner and distributor ecosystem for worldwide availability of Volume Graphics software

Efficient

- Wide range of analyses for all sorts of tasks

- Easy automation of repetitive tasks, including easy replication of analyses across periodic object structures

- Fast handling of huge data sets and analyses

- Seamless digital workflow, from design and correction to inspection and production:

- Use one software for all analyses, including manufacturing geometry correction

- Transfer inspection plans from the lab to production lines

- Share data and results without format conversions

Solutions

- Instructive and insightful results based on analyses that contain all the info required to make decisions

- Validated accuracy of the results (surface determination, material analyses, etc.)

- Competent support pre- and post-sale with short response times

- Worldwide training courses at VG Academy to get you up to speed on using Volume Graphics software

Product Selection

Find Your Volume Graphics Software

VGSTUDIO MAX

Modular software suite offering the complete spectrum of Volume Graphics functionality

VGCORE

For integrating core functionality such as reconstruction or geometry calibration into CT systems

VGPROJECT SDK

For seamlessly connecting CT scanners to Volume Graphics software products

Free Viewer Applications

myVGL for all inspection results and VGMETROLOGY VIEWER for dimensional inspection results