This page is not compatible with Internet Explorer.

For security reasons, we recommend that you use an up-to-date browser, such as Microsoft Edge, Google Chrome, Safari, or Mozilla Firefox.

CT Reconstruction

With Volume Graphics

Computed Tomography Reconstruction with Volume Graphics

In recent years, computed tomography (CT) has established itself as a high-precision measuring method for non-destructive testing. Because CT reconstruction produces a complete representation of a component in 3D from a large number of 2D X-ray images, CT allows the user to draw conclusions about the external and internal structures of a component and its material properties. Thus, CT can answer far more complex questions than, for example, tactile or optical inspection methods.

The Challenge

In CT reconstruction, 2D X-ray images taken from different angles through the component are combined to create a 3D data set. The images can be generated with different CT X-ray imaging methods. But not every CT X-ray imaging method is suitable for every application. Depending on the problem, the object material, the object size, the cycle time, and the required quality, different CT components (X-ray tube, X-ray detector, manipulators) or completely different systems must be used. For example, imaging with cone-beam CT (CBCT) or helix CT (also called helical CT) enables short acquisition times for large objects/components. Line CT offers an object representation with a very low artifact level (scattered radiation).

If a standard geometry like cone-beam CT cannot offer the desired spatial resolution due to geometrical settings, planar CT is recommended. A planar CT system is therefore suitable for so-called laminography and thus for use in the electronics industry, for example, for testing printed circuit board assemblies.

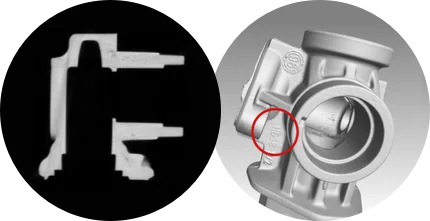

In order to reconstruct a correct 3D image from the 2D X-ray images, software with appropriate reconstruction algorithms and suitable procedures are required to minimize or completely prevent possible image artifacts in the 3D volume. Typical image artifacts are geometry artifacts, scatter artifacts, beam hardening artifacts, ring artifacts, metal artifacts, sampling artifacts, and unsharpness.

The Volume Graphics Solution: CT Reconstruction Integrated into Your Workflow

With its fully integrated CT reconstruction, Volume Graphics offers a seamless connection to the comprehensive analysis and measurement functions of its software.

Moreover, the software is independent of the hardware of the CT system and can process 2D data sets of different CT systems from different manufacturers — all within a single software environment, without interrupting the workflow.

Without beam hardening correction: The incorrect display of gray values (2D slices) causes, amongst other issues, holes in the determined object surface (3D view).

With beam hardening correction: The correct display of gray values (2D slices) and a determined object surface without holes (3D view).

Advantages

Volume Graphics provides users with a future-proof, hardware-independent software solution that integrates seamlessly into their inspection workflow, makes the inspection chain more traceable, and is easy to use:

Comfortable

- Reconstruction can be carried out on modern, commercially available computer systems

- Fast reconstruction through the use of multiple graphics cards

- Geometry correction even after acquisition

- Subsequent calibration of 2D X-ray images, no second scan necessary

- Reconstruction of multiple regions that are relevant for your inspection task in one go

- A variety of tools to achieve the best reconstruction result in the shortest possible time

Integrated

- A one-stop shop for CT reconstruction and CT analysis

- Consolidation of CT measurements and upstream information directly in VGSTUDIO or VGSTUDIO MAX

- No unnecessary data transfer between reconstruction and evaluation computer

- Adaptation of the reconstruction and thus its gray value volume to the respective problem at any time thanks to direct integration in VGSTUDIO and VGSTUDIO MAX

- Customer-oriented workflow

- Seamless integration with VGinLINE, the software for automated CT inspection

Independent

- Numerous artifact corrections independent of the underlying CT system

- Support of different CT system geometries

- Support of different CT system manufacturers

- Continuously ongoing development, independent of the CT system