This page is not compatible with Internet Explorer.

For security reasons, we recommend that you use an up-to-date browser, such as Microsoft Edge, Google Chrome, Safari, or Mozilla Firefox.

Volume Graphics Webinars

Knowledge When You Need It

Computed Tomography Expertise—Online, Anytime

Join our in-house experts in free webinars that cover everything from basic functionality to sophisticated non-destructive testing (NDT) applications using the powerful combination of computed tomography (CT) with Volume Graphics software. Learn about CT-based quality assurance, metrology, quality assurance for additive manufacturing, CT-based simulation, and more! Scroll down to see what new webinars we have in store and to access recordings of past webinars.

Volume Graphics—Your CT Software of Choice

By choosing Volume Graphics software, you can rely on more than 20 years of experience in the development of software for non-destructive testing based on industrial CT. Today, a broad range of global customers, e.g., from the automotive, aerospace, and electronics industries, use Volume Graphics software for quality assurance in product development and production. For an ever-growing community of users around the world, Volume Graphics software gives them a decisive advantage: The ability to gain reliable insights and make better products.

Past Webinars

Past Webinars

Access recordings of previous webinars.

Recent Release Webinars

Smart Manufacturing Series

Methods for Inspecting Series of Parts Using CT and 3D Deep Learning

Sven Gondrom-Linke, Head of Technical Consulting at Volume Graphics / Johannes Knopp, Product Manager Automation & Inline at Volume Graphics)

Empowering Smart Manufacturing through Connecting the Virtual and Physical Worlds

Sachin Mathur, Director Strategic Partnerships & Innovation Program at Hexagon AB

Statistics Fueled by CT

Johannes Knopp, Product Manager Automation & Inline at Volume Graphics / Markus Pfirsching, Sales Engineer at Q-DAS

CT and Complex Designs in AM – How to Get These Designs?

Dr. Thomas Reiher, Director Generative Design at Hexagon

Why Upgrade Series

Remove Distortions from 3D Prints with Volume Graphics Mesh Compensation

Pascal Pinter, Product Manager Material Research & Development at Volume Graphics

Correct Injection Molding Tools Digitally Using the Next Generation Manufacturing Geometry Correction Module from Volume Graphics

Gerd Schwaderer, Product Manager Metrology & CAD at Volume Graphics

Convert CT Scans to CAD Data with the Volume Graphics Reverse Engineering Module

Gerd Schwaderer, Product Manager Metrology & CAD at Volume Graphics

Analyze Deformations and Damage in Materials or Components with the Volume Graphics Digital Volume Correlation Module

Gerd Schwaderer, Product Manager Metrology & CAD at Volume Graphics

What's New Deep Dive Series

What's New 3.5 Overview

Volume Graphics

What's New in Metrology

Gerd Schwaderer, Product Manager Metrology & CAD at Volume Graphics

What's New in Porosity and Material Analyses

Sören Schüller, Product Owner Material Analyses & Product Manager Reco at Volume Graphics

What's New in Tool Correction, Mesh Compensation, and Reverse Engineering

Gerd Schwaderer, Product Manager Metrology & CAD at Volume Graphics

What's New in Reporting

Johannes Knopp, Product Manager Automation & Inline at Volume Graphics

What's New in Simulation and Volume Meshing

Pascal Pinter, Product Manager Material Research & Development at Volume Graphics

CT-Based Metrology Week, July 27-30, 2020

Volume Graphics software gives you a full suite of measurement tools ranging from complex alignments to customizable measurement reports. But what makes Volume Graphics software such a great tool for metrologists? How does it comply with GD&T requirements? How can it be used to measure on assemblies and multi-material objects? And what are the benefits of using a CT-based manufacturing geometry correction?

Join our experts as they answer these questions and more.

Metrology Using CT-Scan Data

July 27, 10:00 AM CEST

July 27, 04:00 PM CEST

In this webinar, learn the basics of taking measurements using voxel data provided by metrology-grade computed tomography (CT) scanners. You will get a quick intro to the technology in which you’ll learn about the pros and cons of CT. We’ll show you how to measure typical components and give a quick overview on which machines to use for what problem.

We look forward to welcoming you at the webinar!

Establishing a GD&T Measurement Plan Using CT-Scan Data

July 28, 10:00 AM CEST

July 28, 04:00 PM CEST

Join our VG Support and Training team member Victoria Andrews and learn how Volume Graphics can help you solve your GD&T tasks. Based on a workflow we've developed for analyzing typical parts, we’ll show you how VGSTUDIO MAX processes CT scan-data. We’ll also show you how the tools in VGSTUDIO MAX make building your measurement plan and inspecting your data more efficient.

We look forward to welcoming you at the webinar!

Fully Digital Workflow for Tool Correction

July 29, 10:00 AM CEST

July 29, 04:00 PM CEST

Modern simulation software is used to design and predict the behavior of molds and tools in production processes. Nevertheless, further adjustments often lead to an iteration process until the final shape is attained. Join our expert Gerd Schwaderer to see why Volume Graphics’ Manufacturing Geometry Correction Module makes it faster and easier for mold makers to update their mold geometry based on CT data.

We look forward to welcoming you at the webinar!

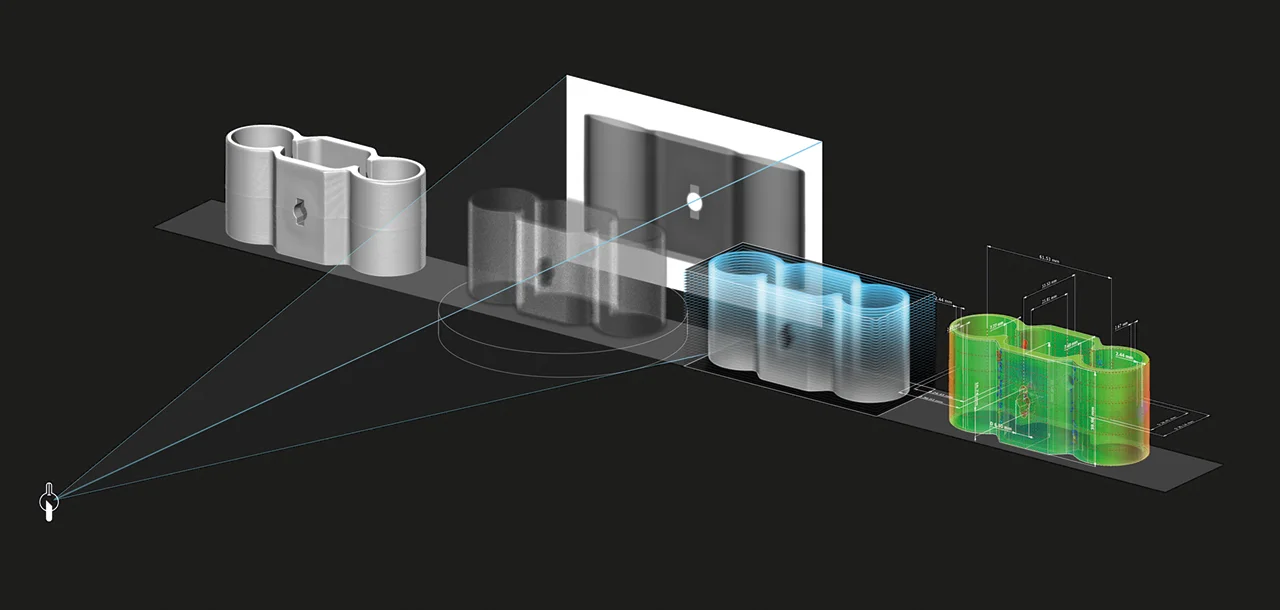

Reverse Engineering of Complex Parts

July 29, 11:00 AM CEST

July 29, 05:00 PM CEST

Reverse engineering is a process that creates CAD geometries from parts when none are available. This can happen for a variety of reasons ranging from old parts without 3D models to handmade parts. Depending on the use case of the part itself, there are several methods that allow the downstream processes to profit from a reverse engineered, physical product. Join this webinar to learn about these methods as well as our new module for CT-based reverse engineering.

We look forward to welcoming you at the webinar!

Measuring in Multi-Material Assemblies

July 30, 10:00 AM CEST

July 30, 04:00 PM CEST

Mounting parts into an assembly via screwing, gluing, or pressing can lead to deformations or defects in the individual parts, which ultimately hinders the assembly process. To inspect this without disassembling the part, industrial computed tomography is required. Join this webinar to learn more about the possibilities of industrial computed tomography to take a glimpse into, measure, and analyze assemblies.

We look forward to welcoming you at the webinar!

Simulation Week, July 6-9, 2020

Join our experts as they discuss how computed tomography serves as a reality check for simulation workflows during the Volume Graphics Simulation Week!

Integrated Computational Materials Engineering (ICME) is a cross-disciplinary simulation workflow within Computer Aided Engineering (CAE). Via integration of simulation workflows across multiple scales and engineering disciplines, ICME considers the influence of manufacturing processes on part geometries and material microstructures and the resulting effects on part performance. While the intent of ICME is to consider all these interactions and effects in the virtual world before physical prototypes become available, real-world data are nevertheless required at various points in the ICME workflow, e.g., for the validation of manufacturing process simulations or the calibration of material models. Real-world data are also required for the simulation of effects of defects in material microstructures in as-built components, such as porosity or fiber misalignments. Industrial computed tomography (CT) is an important source of real-world data for ICME.

How ICME Is Enabling the Optimal Design of Next Generation Materials and Products

July 6, 02:00 PM CEST

Philippe Hébert, Product Manager at e-Xstream engineering, an MSC Company

Improving the Accuracy of Material Models and Part Simulations Using Real-World CT Data

July 6, 04:00 PM CEST

Karl-Michael Nigge, Chief Product Officer at Volume Graphics GmbH

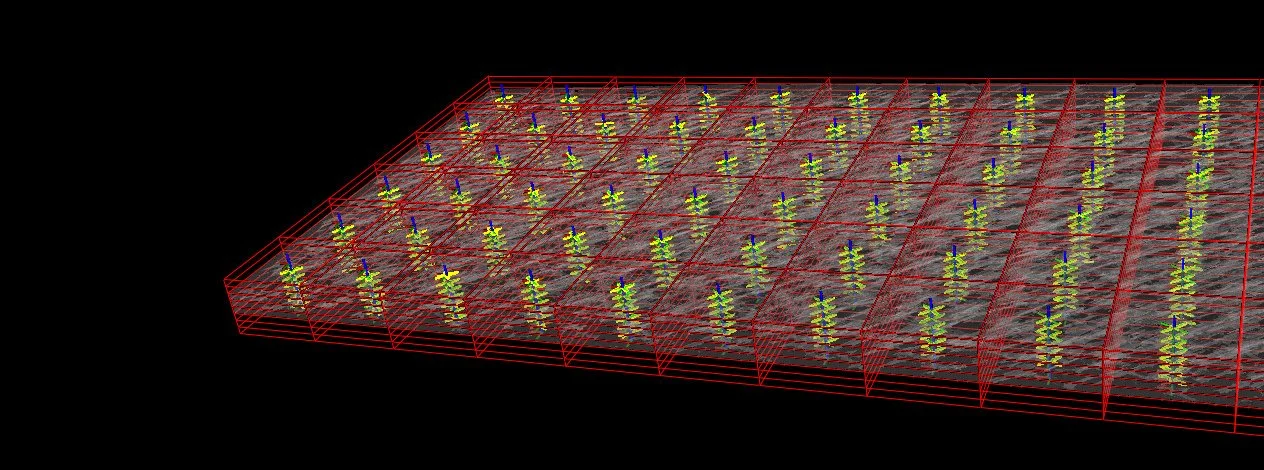

Using Real-World Fiber Orientations to Improve the Accuracy of Simulations

July 7, 04:00 PM CEST

Kai Winter, Sales Engineer DACH & Rest EMEA at Volume Graphics GmbH

Automatic Fiber Placement: Why As-Manufactured Structural Analysis Is a Game Changer

July 8, 02:00 PM CEST

Anthony Cheruet, Business Developer - Aeronautics at

e-Xstream engineering, an MSC Company

Simulation of Effects of Porosity in As-Built Components

July 8, 04:00 PM CEST

Beate Lauterbach, Product Manager & Product Owner Simulation at Volume Graphics GmbH

Structural Simulation of 3D Prints with Geometry Deviations and Material Defects

July 9, 04:00 PM CEST

Beate Lauterbach, Product Manager & Product Owner Simulation at Volume Graphics GmbH

and

Philip Sperling, Product Manager Additive Manufacturing at Volume Graphics GmbH

Additive Manufacturing Week, June 15-18, 2020

From powder to printed part, from lab to fab—Volume Graphics software gives you the insights to constantly push the quality boundaries of your additively manufactured parts and establish efficient workflows. But what can Volume Graphics software do for the quality inspection for additive manufacturing, exactly? How can it assist you in the dimensional characterization of lattice structures? How can you combine meltpool and CT data? And how do you speed up your process parameter optimization with CT?

In our webinars, we cover all these points and take it even further with a look at what happens before a part is manufactured and analyzed with CT and Volume Graphics software. Join our guest talks from MSC Software and simufact, both also part of Hexagon, to learn more about how simulation software is used in the design process and helps to reduce costs in the manufacturing of 3D-printed parts.

Join our experts as they answer these questions and more.

PLEASE NOTE: All events are scheduled for Central European Summer Time (CEST).

Quality Inspection for Additive Manufacturing—from Powder to Part

June 15, 04:00 PM CEST

Quality inspection for additive manufacturing can be challenging due to the intricate inner and outer structures and complex designs of printed parts. Learn more about why and how computed tomography and Volume Graphics software enable you to best conquer these challenges.

Dimensional Characterization of Lattice Structures

June 16, 04:00 PM CEST

From very simple to complex, from regular to irregular, the number of possible designs for lattice structures are endless in 3D-printed parts. Learn more about the powerful measurement capabilities of computed tomography and Volume Graphics software for lattice structure unit cells, an array of unit cells, and the entire part.

CT and Complex Designs in AM – How to Get These Designs?

June 16, 05:00 PM CEST

Who – or what – is responsible for generating the complex designs in AM? Dr. Thomas Reiher / MSC Software, part of Hexagon, introduces in this webinar the capabilities of Apex Software to generate bioni- looking shapes for AM, achieve lightweight designs, and speed up the development process while also saving costs.

Combination of Melt Pool and CT Data in Additive Manufacturing

June 17, 04:00 PM CEST

Get a general introduction to in-situ monitoring in metal AM, learn the benefits of combining melt pool and CT data, and discover which analyses can be conducted on melt pool data with VGSTUDIO MAX.

Speed up Your Process Parameter Development with Computed Tomography

June 18, 04:00 PM CEST

In this webinar, you will learn more about the relationship between process parameters and porosity in AM parts, as well as which information you can extract from CT-based porosity analysis with Volume Graphics software.

Simulation of AM – Virtually Optimize Quality, Time, and Costs

June 18, 05:00 PM CEST

What can you do to increase quality while saving time and costs before a part is even manufactured? In this webinar, Dr. Patrick Mehmert / Product Manager simufact Additive, part of Hexagon, gives examples of how simulation software can identify and avoid manufacturing problems before they occur, how to improve the quality of the manufactured parts, reduce rework effort, and reduce support structures to minimize costs and effort in the manufacturing process.

The Power of CT Week, May 26-28, 2020

Volume Graphics software is the key to unlocking the amazing power behind industrial computed tomography (CT). But what is CT, exactly? How does this non-destructive technology work and how can you best use it to reach your goals? How is it used in today's industries, and where will it take us in the future?

Join our experts as they answer these questions and more during the webinars listed below!

PLEASE NOTE: All events are scheduled for Central European Summer Time (CEST).

What is CT: The Basics

May 26, 04:00 PM CEST - ENGLISH SESSION

Have you always wanted to discover more about how industrial CT actually works? Join us as we walk you through the basics of CT and answers to some of the most commonly asked questions about this powerful NDE technique.

CT in the NDT Landscape: Capabilities and Applications

May 27, 04:00 PM CEST - ENGLISH SESSION

This webinar is perfect for those who are new to the world of non-destructive testing and industrial CT, as well as for experienced users who want to learn about current trends and new areas of application for CT and Volume Graphics software in their daily work.

Industrial 3D-CT Inspection as Part of a Digitized Production Process

May 28, 04:00 PM CEST - ENGLISH SESSION

How does industrial CT combined with Volume Graphics software address challenges faced in production today? What are some examples of inline solutions across industries and what does this digitization mean for the future of Industry 4.0?

Was ist CT: Die Grundlagen

May 26, 10:00 AM CEST - GERMAN SESSION

Wollten Sie schon immer erfahren, wie industrielle CT tatsächlich funktioniert? In diesem Webinar erklären wir die Grundlagen der CT und beantworten einige der am häufigsten gestellten Fragen zu dieser mächtigen NDE-Technik.

CT im Umfeld der zerstörungsfreien Prüfung: Möglichkeiten und Anwendungen

May 27, 10:00 AM CEST - GERMAN SESSION

Dieses Webinar ist perfekt für alle, die neu in der Welt der zerstörungsfreien Prüfung und industriellen CT sind, sowie für erfahrene Nutzer, die sich über aktuelle Trends und neue Anwendungsfelder für CT und Volume Graphics Software informieren möchten.

Industrielle 3D-CT-Inspektion im Rahmen eines digitalisierten Produktionsprozesses

May 28, 10:00 AM CEST - GERMAN SESSION

Wie lösen industrielle CT und Volume Graphics-Software die Herausforderungen moderner Produktionsprozesse? Was sind einige Beispiele für Inline-Lösungen in verschiedenen Branchen und was bedeutet diese Digitalisierung für die Industrie 4.0?

- Discover VGSTUDIO MAX 3.3

- VGSTUDIO MAX 3.3 entdecken

- CT Reconstruction (English)

- CT-Rekonstruktion (Deutsch)

- Automated Quality Assurance with CT

- Automatisierte Qualitätssicherung mit CT

- Quality Assurance for Additive Manufacturing Using CT

- Qualitätssicherung for die additive Fertigung mit CT

- Metrology on CT Data

- Messtechnik auf CT-Daten

- Quality Assurance and Material Research Based on CT

- Qualitätssicherung und Materialforschung basierend auf CT-Daten

- Mold Cavity Correction as a Fully Digital Workflow

- Werkzeugkorrektur als volldigitaler Workflow

- Metrology on CT Data

- Messtechnik auf CT-Daten

- Mechanical Simulation of Complex Materials and Components with Defects

- Mechanische Simulation von komplexen Werkstoffen und Bauteilen mit Defekten

- Automated Quality Assurance with CT

- Automatisierte Qualitätssicherung mit CT