Staying (A)head of the Game

American football is a full-contact sport that originated in the United States from soccer and rugby. Behind the glim and glam of half-time shows and touchdowns are grueling hours of practice and brutal injuries. The sport may boast the highest revenue, but it is also known for having the highest rate of concussion and traumatic brain injury in the sports industry.

Fortunately, more light is being shed on player health and safety. In the 2018-2019 season, the average annual incidence of in-season game concussions had decreased by nearly one fourth compared to 2015. The 2021 preseason—which includes practices, scrimmages, and games—had the lowest rate of concussions in the last five years, excluding the anomalous 2020, which had no preseason games.

This overall decline was partly due to concussion reduction strategies, which include safer tackling techniques and greater penalties for dangerous maneuvers, but also the push for better, safer helmet design. For example, in 2017, only 41 percent of professional league players were wearing top-performing helmets. In 2021, this number had increased to over 99 percent.

An American football helmet (credit: A. Mathers)

Increased awareness resulted in a massive collective effort to improve player safety—not just from coaches and league officials, but also from medical staff and helmet manufacturers. It also called for more testing and research to continue enhancing helmet design.

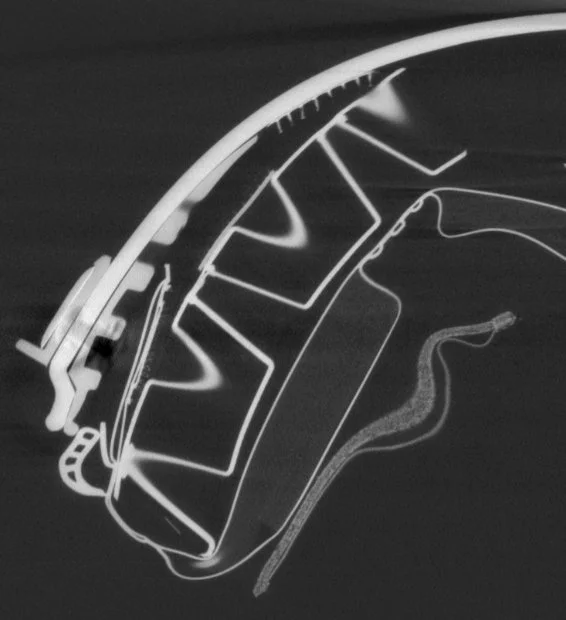

The question is, how complex can an American football helmet be?* Can we perhaps use CT scanning and software to take a quick look inside?

(*The answer: very.)

Challenge accepted. We've always wanted to see inside an American football helmet, so let's see what we can do!

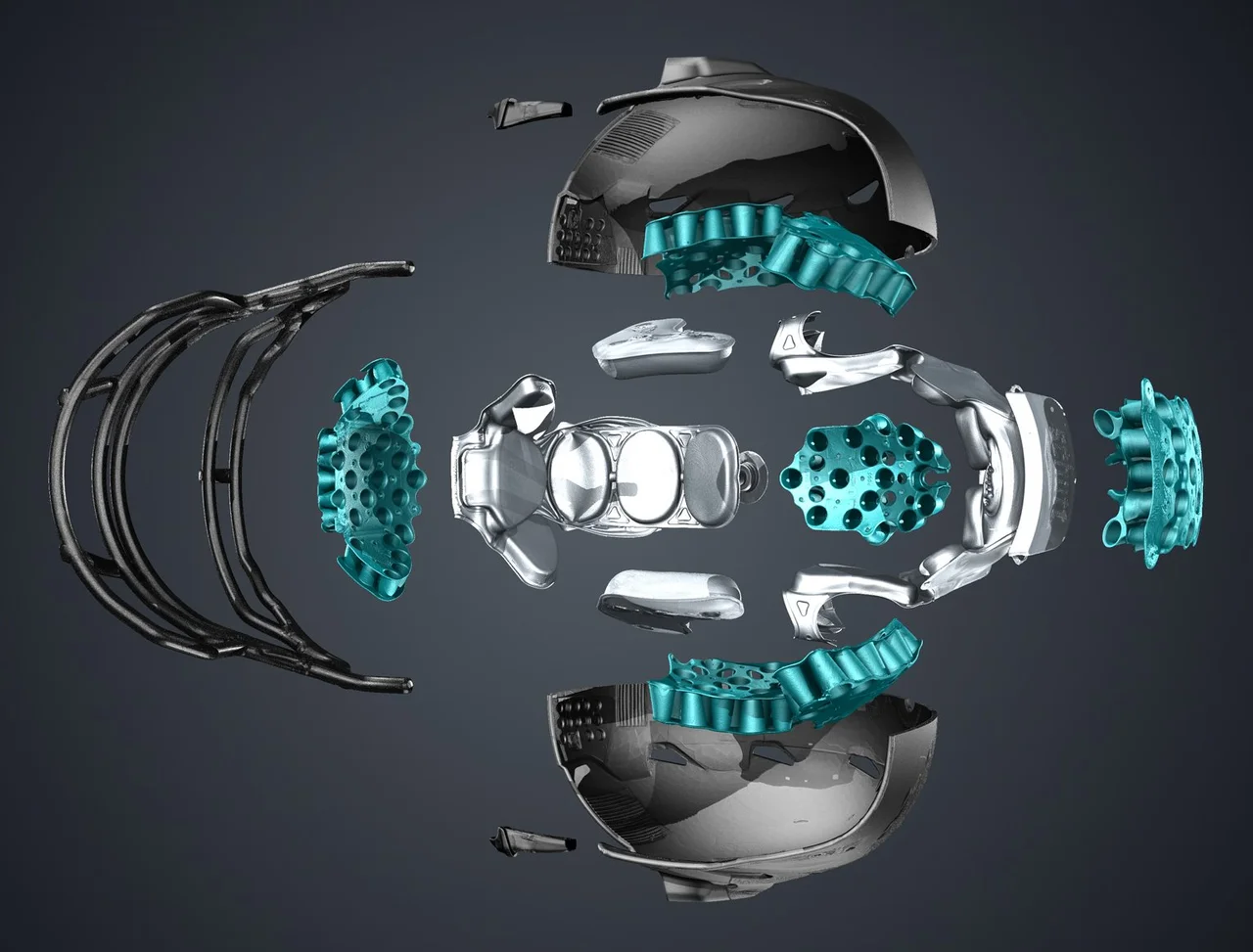

An exploded view of the helmet

The Outs and Ins

Protection against impact only begins at the outer shell of the helmet. The first helmets were developed in the late 1890s, and they were made almost entirely of leather straps and padding. Over time, it became clear that this was not enough, and by the mid-1960s, plastic helmets had completely replaced their leather predecessors.

Let's find out more about the evolution of and idea behind modern-day American football helmets! Join us as we interview Dr. Andrew Mathers, X-Ray CT project manager—and football coach—at Nikon Metrology!

Interview

Thank you for joining us. Before we begin, can you tell us a bit about yourself?

My name is Andrew Mathers, and I am an X-Ray CT Project Engineer and Project Manager at Nikon Metrology. I joined the company in March 2018 as an X-Ray CT Applications Engineer and moved into our European Custom Projects Team in 2020.

Digging a bit further back into your background: Philosophy, X-Ray/CT scanning, and American football are an interesting combination. How did that come about?

My academic background is in environmental science, which I studied at the University of Nottingham (UoN) at bachelors, masters, and PhD level. Following my PhD, I moved into a postdoctoral research position at the UoN Hounsfield Facility, investigating the cellular architecture of plant leaves in 3D with X-Ray CT, which sparked my obsession with the technology.

During my time at University, I played contact American football for 6 years and then turned to coaching both the contact and flag (non-contact) formats of the game. I’ve been very fortunate over the past 15 years to work with some of the very best coaches and players in the UK game at the University of Nottingham, Nottingham Honey Badgers, Tamworth Phoenix, and the Great Britain Lions National Programme.

The helmet, which is my own from my playing days, seemed like a worthy challenge for X-Ray CT, seeing as it is a relatively large object (L: 320mm W: 250mm H: 250mm), is multi-material (stainless steel, aluminium, cloth, plastics and foams), and possesses fine features.

Shot of Dr. Andrew Mathers with his head in the game. (Credit: 39 Design Photography)

Let's talk a bit about the football helmet. A few weeks ago, we did a story on designing an Olympic skeleton helmet. What makes a football helmet different from other sports?

Unlike many other sports helmets, American football helmets are designed to last years of punishment and provide protection for the athlete against hundreds of impacts, rather than protection against a large single impact event (motor racing, cycling, horse riding, etc.), which typically renders the helmet unusable or necessitates immediate refurbishment. However, like all sports helmets, the quality of the fit is essential not just to the athlete’s performance, but also its own performance.

What was the biggest challenge you faced when segmenting the football helmet?

Once assembled, most of the helmet’s interior components fit very tightly together and are made from similar materials (lightweight plastics and foams); therefore, these components exhibit very similar densities under X-Ray, which can be challenging to segment from one another when you are working with grayscale voxel data.

Tightly fit components that cover almost the same gray value area are challenging for segmentation

Any favorite tips or tricks you'd like to share with our users?

I’ve always thought that the bookmarks tool is one of the most underutilized and undervalued features within Volume Graphics. It is incredibly useful when quickly reviewing data with colleagues or customers; the ability to seamlessly switch between different viewing modes, render settings, coordinate systems, 2D slice orientations, and analyses to focus on features of interest, is invaluable! In addition, I find bookmark templates extremely useful for adding custom images to automated analysis reports via VGSTUDIO MAX macros or VGinLINE.

(Editor's addition: check out our quick story on the joy of bookmarks!)

Do you have a favorite segmentation tool?

The polyline selection mode is very useful for creating regions of interest to encapsulate components with complex geometries or focus on individual components among others with similar densities. These ROIs can then be used in combination with the region growing tools to easily segment individual components from their surroundings.

Segmentation with Freeform Surfaces

Using geometry elements for segmentation is not entirely new, but freeform surfaces specialize in areas in which everything is curved and distorted: just fit one to the surface you are interested in and create an ROI from it!

Here are a few pointers:

- Make sure you've chosen the right fit point filter options, such as search and safety distance

- If large-area fitting is difficult, cover smaller areas with several freeform surfaces and create a single ROI from all the little patches

- If "Smart expand" goes way beyond what you had in mind, go with "Single point" and set fit points manually

- If a surface determination doesn't help, such as when you're working on a gap between two same-density parts that is barely visible, disable "Snap fit points to surface" in the "Fit points" tab and turn off "Auto fit points" to have full control. Unfortunately, this also means that you'll have to do the work manually to achieve the desired result

- Oh, and don't forget! You can always switch off the snapping mode to eyeball placing your fit points.

If you're still not satisfied with your ROI, here are some extra tools to help you out:

Polyline 3D

A few precise cuts with the Polyline 3D can work wonders. It's our weapon of choice when it comes to cutting away things we don't want.

Region Grower

Set a seed point and feel your way to a threshold that won't spill over to other components. Now add the growth to your ROI and gradually set the seeds at other points of the part you want. Add these areas as well. This way, you can carefully add small bits to your ROI.

Draw Tool

If you see that your ROI is missing a few voxels, just grab a pen! The same goes for when you need to shave off unwanted parts. Just hold down "Shift" while you draw.

What about rendering?

For medium to high density manmade objects, I typically use the Isorender with transparency applied, whereas for low density manmade objects or natural samples, I use the Phong and X-Ray renders. If you want to go a step further for natural samples which possess a skeleton, using the isorender for the skeleton and the X-Ray or Phong renderer for the soft tissues (different volumes overlaid within the same image) can produce captivating results. Using different light source conditions, angles, and colors in combination with shadow can also really make your renderings pop!

My favorite new addition to rendering in VGSTUDIO MAX is the ambient occlusion feature, which gives 3D renderings a real sense of depth and contrast.

Let's talk football again. Have you noticed a change in football safety over the years? How do you think CT technology can impact sports safety in the future?

There has been much discussion over the last decade about the level of player safety, in particular the incidence and frequency of concussions, and the potential adverse effects this can have on a players’ health in later life. In response to this increased awareness, team coaches, medical staff, league officials, sports safety educators and helmet manufacturers have all played their part in trying to improve player safety. This has resulted in league rule changes, the introduction of different tackling techniques, better education for coaches and players at all levels (and ages) of the game, harsher penalties for dangerous play, revised medical protocols for concussion evaluation and return to play eligibility, and of course helmet design.

I imagine, and I hope X-Ray CT will play an integral part in improving the safety of sports equipment in future. The ability to non-destructively inspect the build quality, correct manufacturing errors and simulate the performance of the individual components themselves as well as the fully assembled equipment provides an invaluable contribution to the product design cycle and iterative innovation process.

A typical modern-day American football helmet like the one I scanned consists of the following components, all of which come in a range of shapes and sizes to maximize comfort, fit, performance and ultimately safety:

- a lightweight polycarbonate outer shell which helps deflect or delocalize the force of impacts

A typical helmet has an outer shell made of a molded polycarbonate that is both lightweight and able to deflect and delocalize the force of impact. This exterior is usually 3.35 mm thick

- a metal facemask, typically constructed of stainless steel, titanium, or carbon steel, wrapped in a Polyarmor 17 thermoplastic coating, which is impact and corrosion resistant

Modern face masks are coated with Polyarmor G17, which is a thermoplastic powder coating that is resistant to impact, abrasions, and corrosion

- an adjustable chin strap system with either a hard polycarbonate or soft cloth cup, depending on the athlete’s preference, which is fastened at multiple mounting points on the outer shell to help secure the helmet firmly in place

Segmenting the chin strap, which can be fastened at multiple mounting points on the outer shell

- a pair of cheek pads and a forehead pad array, these components are typically filled with impact absorbing foam or a series of air pockets to help absorb and dissipate high velocity impacts

Jaw and forehead pads are usually filled with foam (highlighted in red) to help absorb high-velocity impact

- shock-absorbing structural elements for the top, back and sides of the cranium, including foam padding, a thermoplastic matrix and interconnected systems of inflatable bladders to ensure a high-quality fit for any head shape

Shock-absorbing structural elements both cushion and support the top, back, and sides of the cranium

Definitely. We've already seen this in the main components of the American football helmet. Is there anything else to take into consideration?

Other helmet components designed for safety in the modern game include:

- flexible panels within the construction of the outer shell, such as in the forehead region, which move to absorb and dissipate the force of impact,

- impact loggers and sensors which provide real time or recoverable data to monitor an athlete’s exposure to impacts, including the direction, location and force, and

- visors which attach to the facemask to prevent eye injuries from physical contact, protect eye health by reducing dirt ingress from the playing surface, and improve visibility by reducing glare; in some cases, tinted or colored visors are worn to help assist players with chronic eye conditions.

Thank you for your time, Andrew. Any last words for our readers?

The fundamental key to unlocking the full potential of Volume Graphics to generate truly exceptional images, lies within the quality of the raw X-Ray CT data you provide it with. If you really take your time to ensure your samples are intelligently mounted—you use the optimal X-ray beam filtration, ensure your scan settings allow for high flux, contrast, and resolution coupled with low noise and absence of artefacts—you’ll have the perfect starting data set to take advantage of all the superb features Volume Graphics has to offer.

Think of it like taking a photograph… if you capture a photo that is out of focus and badly exposed with a camera on a wobbly tripod, it doesn’t matter how awesome your image editing software is, the resultant quality will still be poor.

Thanks again to Dr. Andrew Mathers for joining us from Nikon Metrology!

Ready to Learn More?

Users of VGSTUDIO MAX can find out more about segmentation, visualization, and rendering in the tutorials included in the software.

Got a Story?

If you have a VG Story to tell, let us know! Contact our Storyteller Team at: storytellers@volumegraphics.com. We look forward to hearing from you.