This page is not compatible with Internet Explorer.

For security reasons, we recommend that you use an up-to-date browser, such as Microsoft Edge, Google Chrome, Safari, or Mozilla Firefox.

What's New in VGSTUDIO MAX

Discover the Exciting New Capabilities of Version 2022.2 (as of June 2022)

Version 2022.2 of VGSTUDIO MAX is now available for download. In version 2022.2, you will benefit from the following new capabilities*:

File Input/Output

Simplified Rigaku Volume Import

We have simplified the import of volume data from Rigaku CT systems. You no longer need to manually adapt settings during the import process. The software now accurately recognizes all mirroring options and imports gray values as 16-bit integers by default.

Filter

Increased Erode/Dilate Radius

Use the "Erode/dilate" function for ROIs with a radius of up to 32 voxels. The increased radius means you no longer have to perform the function multiple times.

Coordinate Measurement

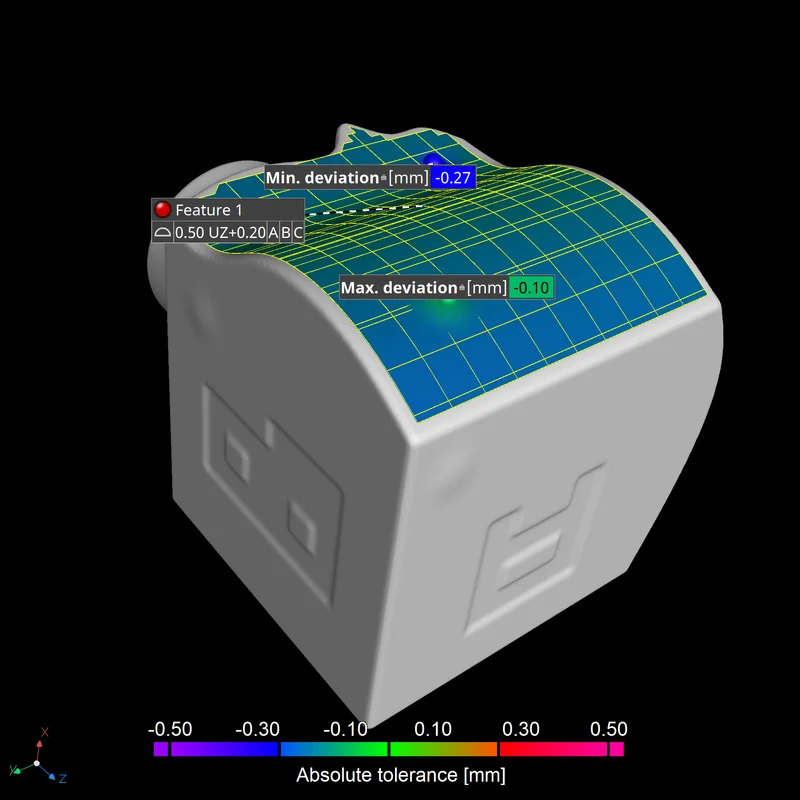

Native Support for Nonsymmetric Tolerance Zones

Measure unequally disposed tolerance zones of profile tolerances. You can now inspect nonsymmetric tolerance zones of profile tolerances in a single step and at the same time define the tolerance zone more accurately. Additionally, the standard UZ modifier is supported in the tolerance callout.

Porosity/Inclusion Analysis

P 203 Porosity Analysis Supports "From defect ROI"

You can now evaluate defect masks—described by an ROI—with the P 203 analysis. This allows you to use the convenient standardized key-based tolerance specification method of the P 203 analysis to evaluate defect masks obtained via arbitrary methods, for example, via external analyses.

Display Whether Image Quality Is Sufficient for P 203 Analyses

See directly on the "Settings" tab if the image quality is sufficient for a P 203 analysis. The quality factor provides a visual indicator about whether the quality is sufficient—green for OK and yellow for possibly insufficient. An additional tooltip provides a more detailed explanation of the quality factor.

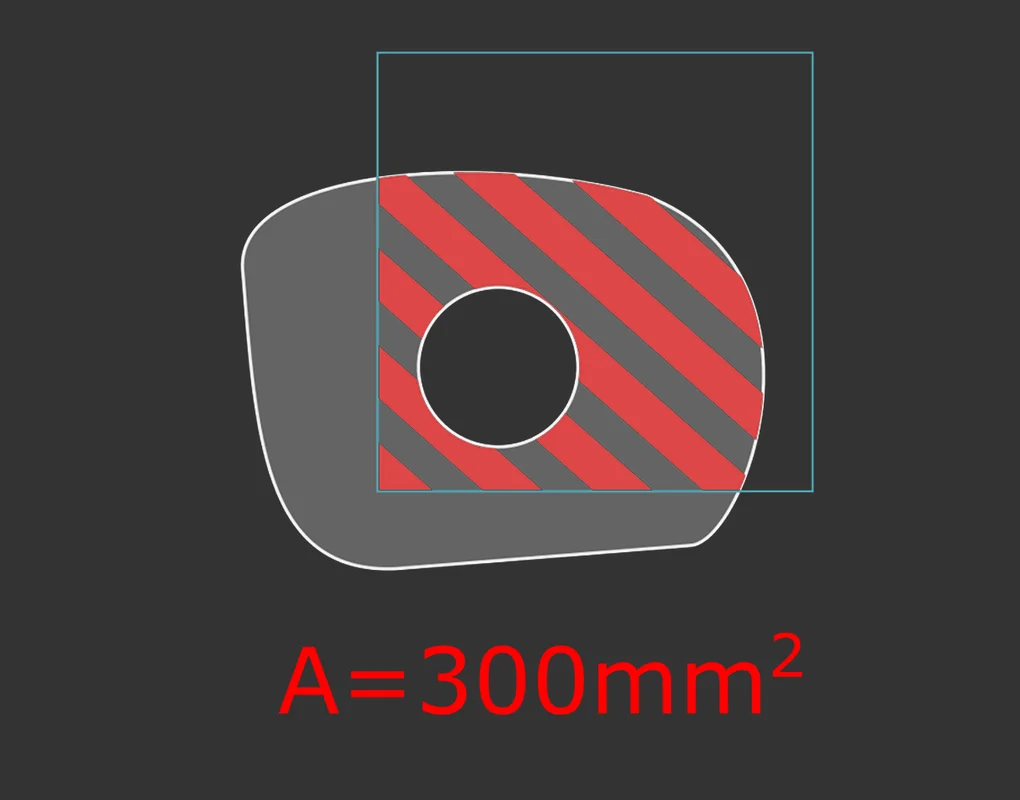

Slice Area Analysis

New Slice Area Analysis

Easily measure the area of a cross section. With our new slice area analysis, you now have a way of calculating the area of a region of interest (ROI) or a volume or the area enclosed by the surface determination in a slice.

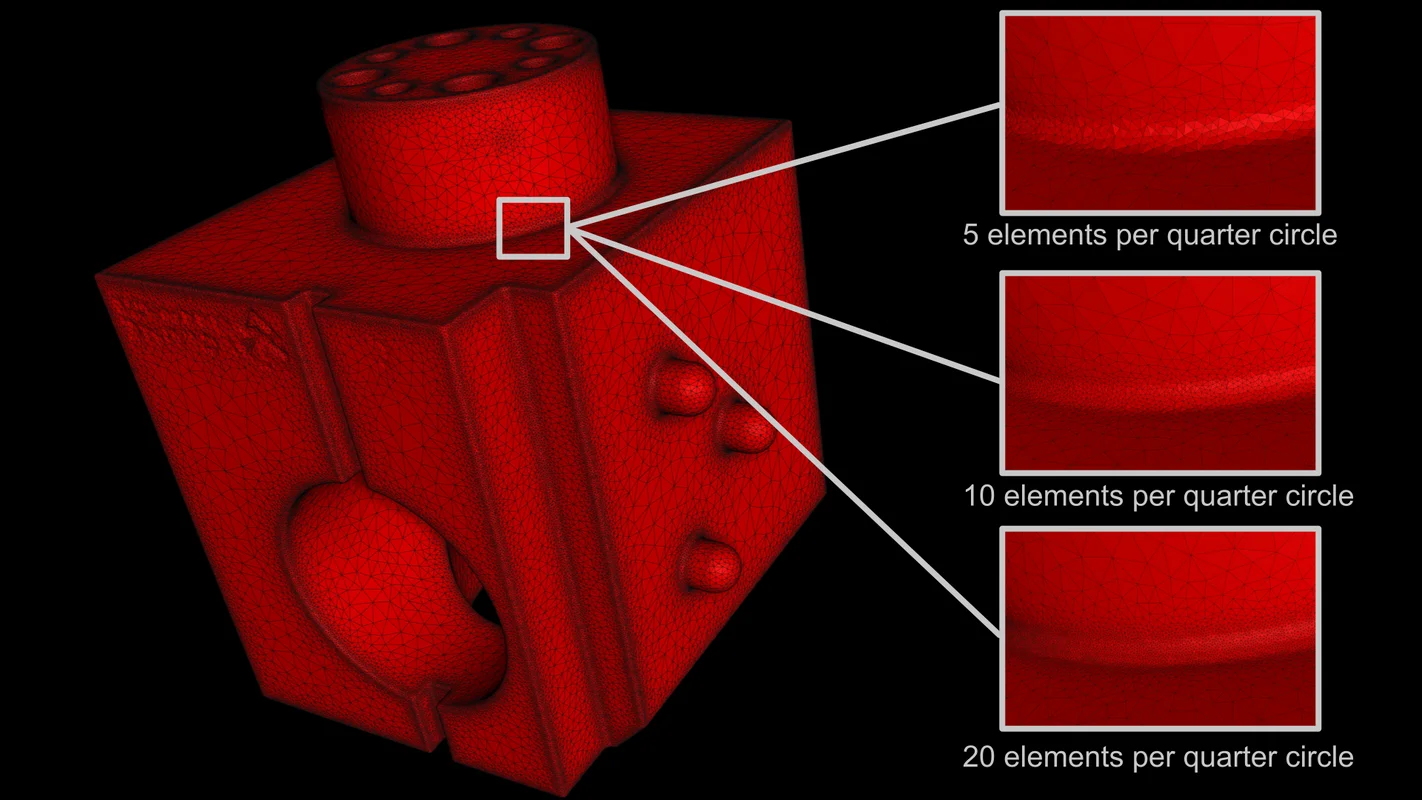

Volume Meshing

Curvature-Based Refinement

Locally refine a volume mesh based on the local curvature of the surface. You can now accurately mesh a part's surface based on its local curvature, while using larger elements for the internals and still maintaining good element quality. This speeds up any calculations done on the resulting mesh compared to homogenously refined meshes.

Reporting and Traceability

Sorting of Features Either by ID or by Name in Q-DAS Export

Export coordinate measurement features in the Q-DAS ASCII transfer format in a sensible order. This allows you to define the coordinate measurement features in an order that fits your workflow without having to use this same order in exported Q-DAS files.

Part Information for All Features in Q-DAS Export

Export results in the Q-DAS ASCII transfer format and associate them with part information. This provides more complete information about individual features used in statistical process control by storing relevant part information for all of them, instead of only the first one.

Vertical Lines in Report Tables

The new option to show vertical lines for tables in reports allows for a clearer visual separation of the data in result tables and makes it easier to navigate in tables that consist of many columns.

FAQ for the Integrated Reporting

Get started with and learn more about the integrated reporting with our new FAQ page. This page helps you to quickly become productive with the integrated reporting by providing answers to frequently asked questions in one easily accessible location and gives a good overview of the integrated reporting's capabilities.

Coloring for Tolerancing in Coordinate Measurement Tables in Reports

Create easy-to-understand reports of coordinate measurement results. Coloring for tolerancing immediately highlights the tolerance states of the measured features in a report table and thus makes it easy to focus on the most relevant results.

Overview Tables for Analyses in Reports

Analyze multiple parts or regions in the same way with either porosity/inclusion analysis, nominal/actual comparison, wall thickness analysis, fiber composite material analysis, gray value analysis, or ASTM and report the results. Overview tables for analyses allow for an intuitive comparison of similar results at a single glance and remove the need for external tools to create comparison tables.

General

Automatic Settings Import from Previous Versions

Keep your user settings when you upgrade to a newer version of the software. User settings are now automatically transferred from a previous version on the first start of a newly installed version, removing the need to manually configure the software. If desired, you can still manually reset the settings to the factory default.

VG News Link in "Help" Menu

Access relevant news on the Volume Graphics website directly from within Volume Graphics software. A new link in the "Help" menu makes it easy for you to learn about recent changes in the software version you are using.

*Depending on the platform, there are differences in the range of functions for different operating systems. See our continuously updated Product Information page for details.

Volume Graphics GmbH

Speyerer Straße 4-6

69115 Heidelberg

Germany

Phone: +49 6221 73920 60

Fax: +49 6221 73920 88

Sales enquiries:

sales@volumegraphics.com

Modifications and errors reserved.