This page is not compatible with Internet Explorer.

For security reasons, we recommend that you use an up-to-date browser, such as Microsoft Edge, Google Chrome, Safari, or Mozilla Firefox.

Version 2022.1: Introducing Our Game-Changing Adaptive Measurement Templates

Version 2022.1 offers much more than a brand new version number. In our latest release, users can look forward to shape-following adaptive measurement templates, using ROIs as a boundary for sphere-based wall thickness analysis, locking areas during mesh compensation, and comparison tables for coordinate measurement results, among other new and exciting features.

Delivering More Features More Often

We believe that users should enjoy new features as soon as possible. That's why, starting now, we'll deliver new features and improvements much more frequently, and not just as part of one major release per year. Version 2022.1 marks the beginning of a fundamentally new release rhythm at Volume Graphics, with a targeted quarterly frequency. Our new calendar versioning makes this change in the release rhythm evident. New customers will benefit from our regular update rhythm right from the start, as each license comes with a one-year update/service agreement, giving access to the latest software version when it is released.

Shape-Following Adaptive Measurement Templates

Save 50% or more time with adaptive measurement templates that follow the shape of distorted parts. With adaptive measurement templates, a measurement plan created using the nominal CAD data or imported via PMI can be easily applied to even strongly deformed parts. The measurement points are placed at the optimal positions on the actual part and perfectly follow the distorted shape.

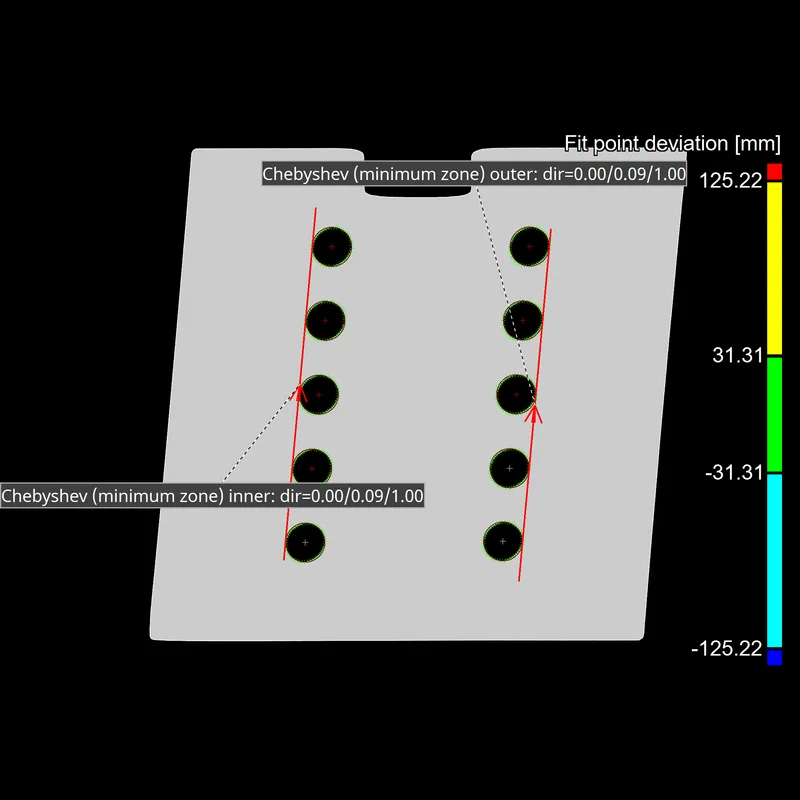

Chebyshev Fit Option for Point, Line, and Torus Geometry Elements and Combined Elements

The user interface for geometry elements and combined elements has been enriched with several methods to combine the information of geometry elements, such as Chebyshev fitting methods for point, line, and torus elements, as well as possible combinations. Element type and fit method are now separate controls, which makes for more intuitive use.

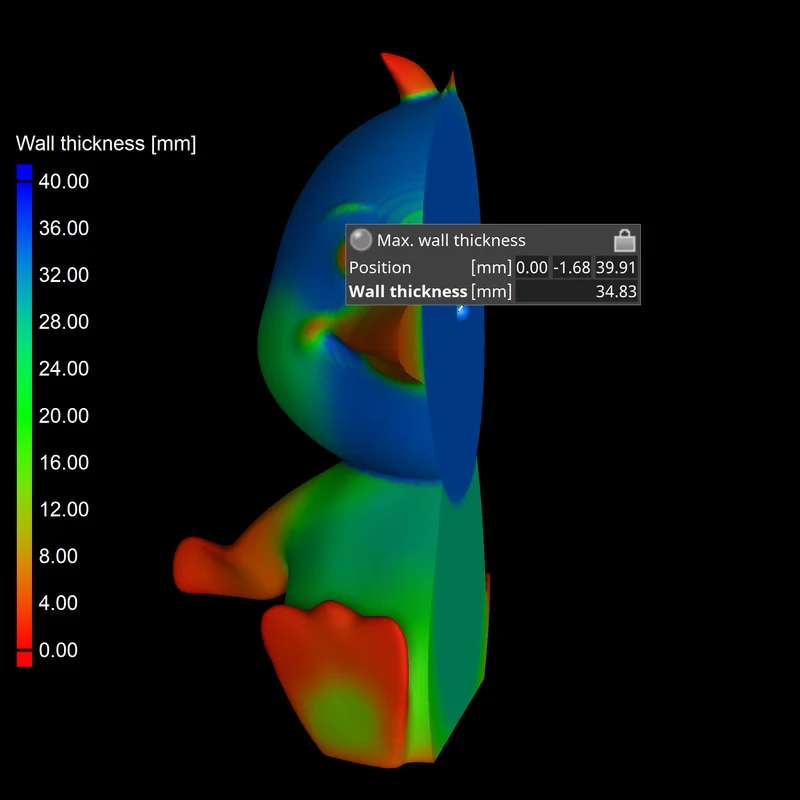

Detecting Maximum Material Accumulation

Find the area of highest material accumulation in a part using sphere-based wall thickness calculation. In casting and 3D-printing processes, the main cause of warpage is uneven cooldown, which can lead to severe distortions. Finding excess material can help identifying these warpage issues.

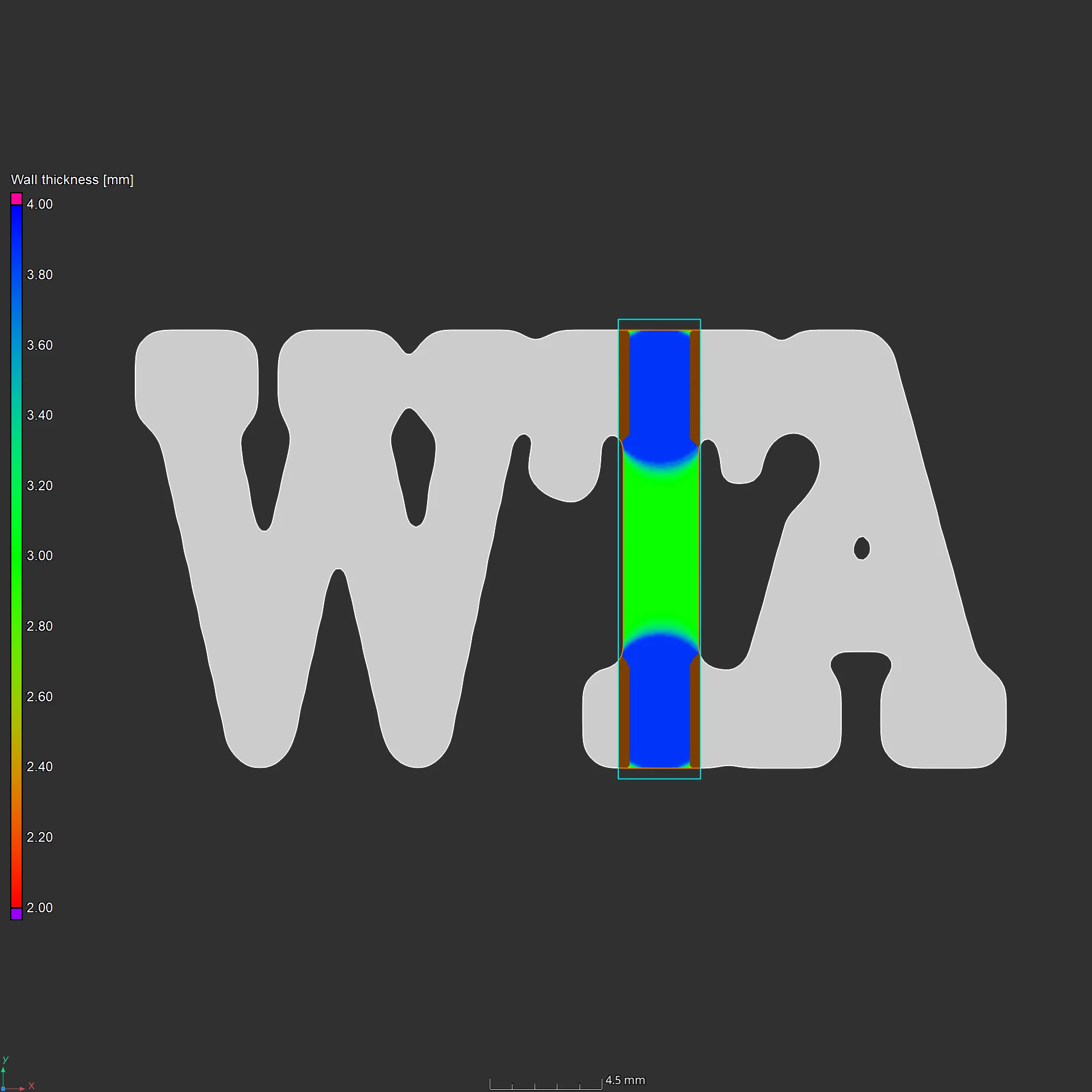

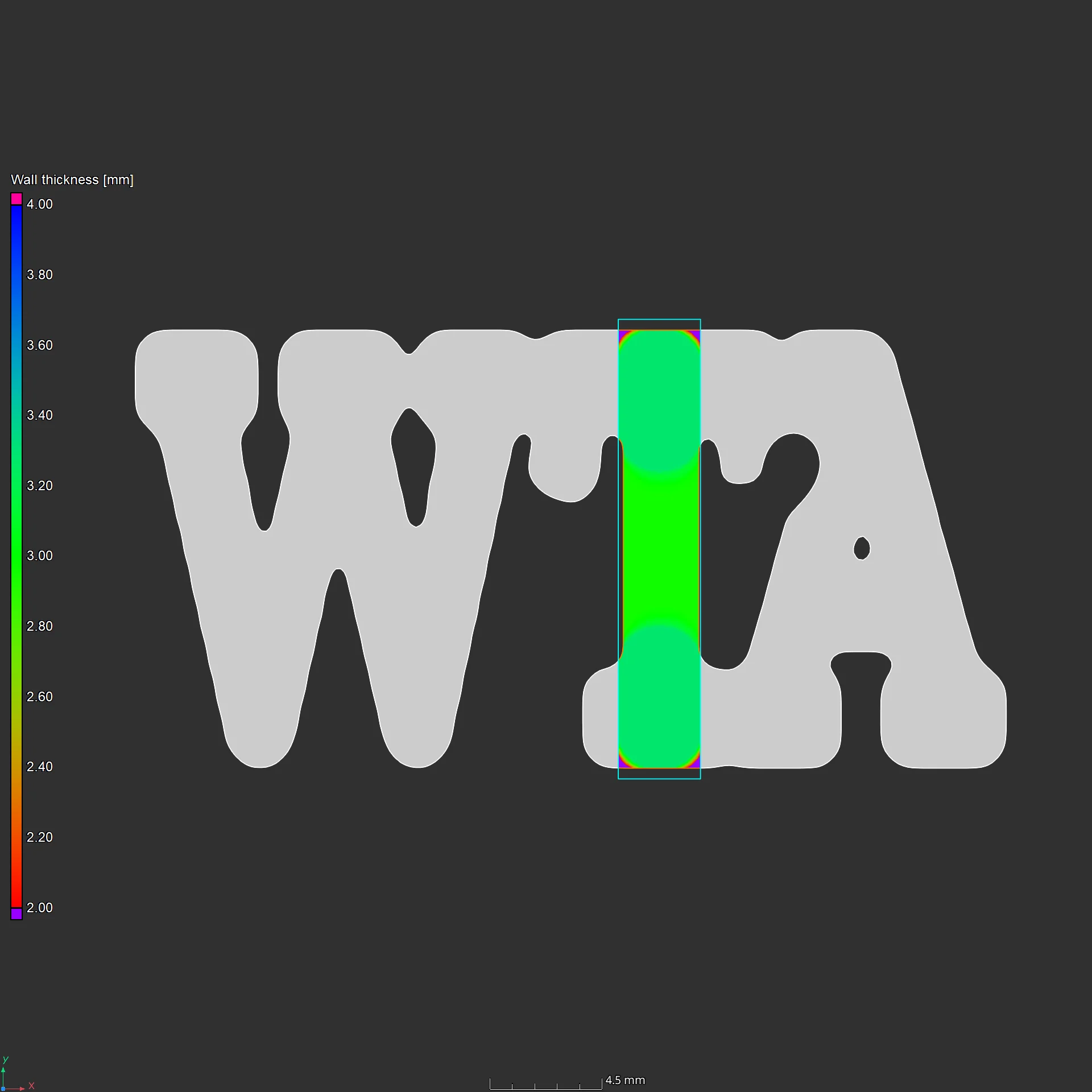

Using ROIs as a Boundary for Sphere-Based Wall Thickness Analysis

It is now possible to use an ROI as a surface boundary for a wall thickness analysis. Users can now decide whether the result of a sphere-based wall thickness analysis should consider the actual material of the part to its full extent, which can lead to a large value very close to the ROI boundary, or whether the calculation should stop there, which will lead to a smaller value as a virtual surface gets introduced.

Locking Areas during Mesh Compensation

Users can now lock specific areas, preventing them from changing during mesh compensation. Areas that are already close to perfect or must not change shape because of manufacturing constraints, such as a base plate in additive manufacturing, can be forced to stay unchanged. The software will then only compensate a defined ROI while keeping the surrounding volume identical.

Faster Uniform Control Point Calculation

An optimized and much faster uniform control point calculation method allows users to process a larger number of control points with improved mesh compensation performance. This means that it is possible to compensate very complex parts, such as lattice structures that need a large number of control points, and parts that need compensation with high granularity and lots of local changes.

Comparison Tables for Coordinate Measurement Results

Measure multiple parts in the same way and compare their results. This new feature allows for intuitive comparison of similar results at a single glance and eliminates the need for external tools to create comparison tables.

Faster Sphere-Based Wall Thickness Calculations

Sphere-based wall thickness calculation times are now significantly shorter. For ROIs, the calculation is in some cases up to ten times faster.

*Depending on the platform, there may be differences in the range of functions for different operating systems. See our continuously updated Product Information page for more details.

Learn More

Learn in detail about what's new in version 2022.1 on our dedicated overview pages for: VGSTUDIO MAX, VGSTUDIO, VGMETROLOGY, and VGinLINE.

Availability of the New Version

VGSTUDIO MAX 2022.1, VGSTUDIO 2022.1, VGMETROLOGY 2022.1, and VGinLINE 2022.1 are available now. Volume Graphics is happy to provide quotes upon request.

Volume Graphics offers free evaluation versions of VGSTUDIO MAX 2022.1, VGSTUDIO 2022.1, and VGMETROLOGY 2022.1 for temporary use.

myVGL 2022.1 is available free of charge and can be requested on the Volume Graphics website.

About Volume Graphics and Hexagon

Volume Graphics GmbH has been developing software for non-destructive testing based on industrial computed tomography (CT) for over 20 years. Customers around the world, e.g., from the automotive, aerospace, and electronics industries, use Volume Graphics software for quality assurance in product development and production. In addition to its headquarters in Heidelberg, the company has branches in the USA, Japan, Singapore, and China. Learn more at www.volumegraphics.com and follow us @volume_graphics.

Since 2020, Volume Graphics has been part of Hexagon. Hexagon is a global leader in sensor, software and autonomous solutions. We are putting data to work to boost efficiency, productivity, and quality across industrial, manufacturing, infrastructure, safety, and mobility applications. Our technologies are shaping urban and production ecosystems to become increasingly connected and autonomous – ensuring a scalable, sustainable future.

Hexagon (Nasdaq Stockholm: HEXA B) has approximately 21,000 employees in 50 countries and net sales of approximately 3.9bn EUR. Learn more at hexagon.com and follow us @HexagonAB.