This page is not compatible with Internet Explorer.

For security reasons, we recommend that you use an up-to-date browser, such as Microsoft Edge, Google Chrome, Safari, or Mozilla Firefox.

Tool Correction and Mesh Compensation

with VGSTUDIO MAX

The tool correction and mesh compensation features in VGSTUDIO MAX allow you to make informed changes to the manufacturing data in order to influence the actual physical part. Their sophisticated functions enable you to correct mold geometries for part warpage and shrinkage, and to optimize 3D printing input by compensating part warpage in additive manufacturing.

Tool Correction Features

Use the manufacturing geometry correction functions to optimize your tools or 3D printing geometries. The software uses scans of your sample part to calculate suggestions for necessary changes to tools and molds in order to minimize iterations.

With the manufacturing geometry correction features, you can:

- Optimize the mold to compensate for part warpage and shrinkage.

- Correct the tool based on points, curves, or surfaces to help the mold maker redesign the product.

- Compensate the part if the mold is created parametrically from it.

- Reverse engineer surfaces on the scan.

Compensate and Export Points

To compensate and export points, which can also be based on user input, you can use the manufacturing geometry correction features to:

- Replicate the typical workflow in which only arbitrary or defined points are chosen, compensated, and exported as a .csv file for the mold maker.

- Use a more sophisticated workflow incorporating cubic surfaces of the part or mold which are based on a set of points rather than surfaces. This enables a parametric workflow in the CAD system that replaces the source points with the compensated points.

- Import specific points and export their compensated descendants as a .csv file.

Compensate and Export Sections and Curves

To compensate and export sections and curves, you can use the manufacturing geometry correction features to:

- Work on areas forming a closed loop in the part, such as sealing surfaces or cavities, which are often too narrow or complex to be compensated by single surfaces.

- Compensate a section, enabling the CAD system to perform simple lofting functions with draft angle. This approach allows for more control and therefore higher manufacturability than using free form surfaces.

- Export the section information as curves or points.

Compensate Surfaces and Patch Compounds

To compensate surfaces and patch compounds using a rigid realignment while adhering to manufacturing constraints, you can use the manufacturing geometry correction features to:

- Only move a mold while keeping the parametrization and shape of it. This ensures easier reintegration in the CAD model, manufacturability, and easier creation of milling strategies compared to creating a free-form geometry.

- Create constraint canonical geometry with constraint size and orientation, i.e., fit a cylinder with specific diameter and orientation to a compensated point cloud.

- Split entire patch compounds from the CAD model and realign them to a compensated point cloud while maintaining control over all degrees of freedom.

Replace Geometries with Free-form Surfaces

To replace geometries with free-form surfaces while maintaining full control over their parametrization and smoothness, you can use the manufacturing geometry correction features to:

- Achieve the best compromise between accuracy, smoothness, and manufacturability by interpolating points in an iterative process.

- Create free-form surfaces with a defined number of control points, smoothness, and tension as well as visualize the deviations and quality of the surface.

3D Printing Mesh Compensation Features

Additively manufactured parts are often deformed. Such distortions are inherent in the 3D printing process and may even remain after completing a previous optimization based on a 3D printing simulation. You can easily create a surface mesh that compensates for the difference between the actual object and reference object—directly from the CT scan using mesh compensation (part of the Manufacturing Geometry Correction Module).

With mesh compensation, you can:

- Compensate the mesh sent to a 3D printer to eliminate deviations in the actual geometry caused by distortions such as warpage from internal stresses, uneven heat, and uneven volume distribution. Creating compensated, print-ready meshes reduces the time to market compared to the conventional trial-and-error approach.

- Add remaining deviations of a print based on compensated data to the first corrected mesh in order to allow for a second compensation iteration.

- Use the full spectrum of functionality within the metrology package, such as alignments, GD&T analyses, or creating a golden surface to average the overall deviation of a batch of parts.

Arbitrary, Defined, and Gridded Anchor Points

Chose arbitrary, defined, or gridded anchor points for the compensation:

- Arbitrary anchor points are perfect for organic, smooth-shaped geometry.

- Gridded anchor points are perfect for complex geometry with a lot of small details.

- Defined anchor points are perfect for parts containing important mechanical elements.

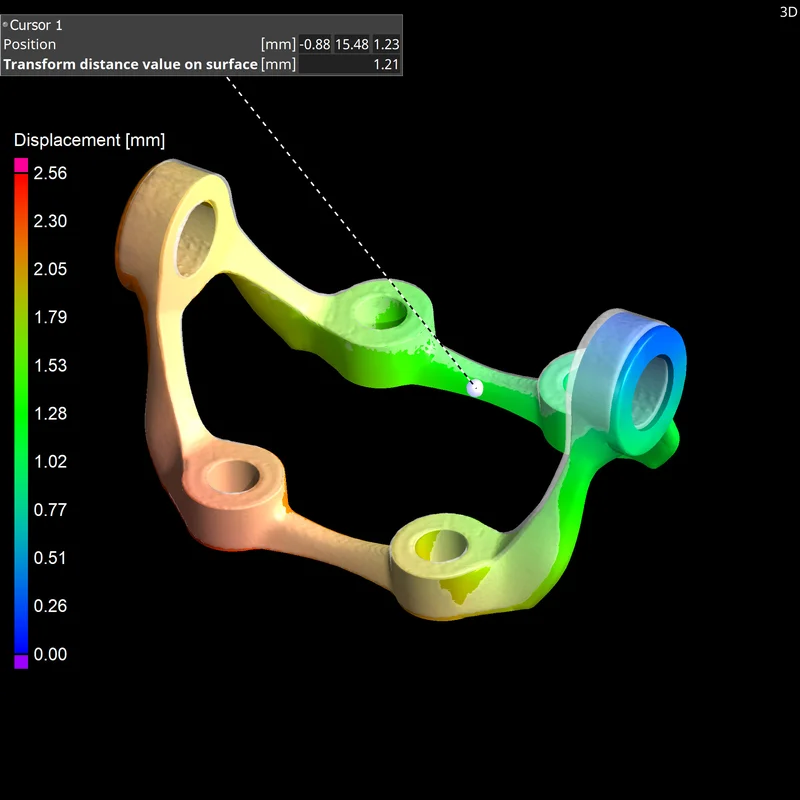

Visualize Distortion

Mesh compensation often lets you visualize, understand, and document part distortion better than a nominal/actual comparison because a nominal/actual comparison may fail to show deviation of overlapping areas even if the region may have moved.

With mesh compensation, you can:

- Visualize displacement of the whole part.

- Create annotations.

Benefits

- Direct communication between metrology and manufacturing.

- No need for an additional CAD system to optimize manufacturing geometry for molds and 3D printing.